Architects Foster + Partners have completed a winery clad in Corten steel shingles in the Ribera del Duero region of Spain.

Called Faustino Winery, the three arms of the concrete structure each house a stage of production; fermentation, ageing in oak barrels and ageing in bottles.

The parts of the building containing the wine barrels are partly embedded into the ground to provide the best conditions for maturing the wine whilst the fermentation wing is exposed, allowing carbon dioxide to be released.

A road rises to the roof of the structure where harvested grapes are collected.

Inside the building a glazed mezzanine stretches deep into the wings and provides views of each area and the different processes occuring within.

The 12,500 square-metre facility has a production capacity of one million bottles per year.

Photographs are by Nigel Young, Foster + Partners.

Faustino winery opens in Spain, 1 November 2010.

Bodegas Portia

Gumiel de Izan, Ribera del Duero, Spain

2004 –2010

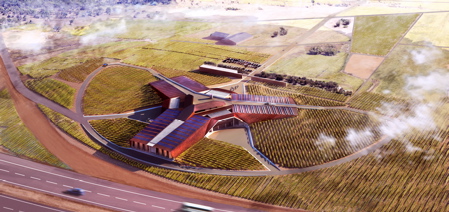

Bodegas Portia is a new winery for the Faustino Group in the Ribera del Duero, one of Spain’s foremost wine-producing regions. The project is Foster + Partners first winery and was an opportunity to look afresh at the building type, using the natural topography of the site to aid the winemaking process and create the optimum working conditions, while reducing the building’s energy demands and its visual impact on the landscape.

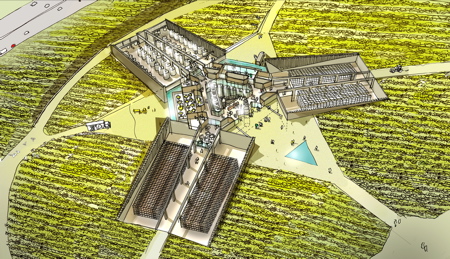

The 12,500 square-metre facility has a production capacity of one million bottles per year. The building’s trefoil design expresses the three main stages of production: fermentation in steel vats; ageing in oak barrels; and finally, ageing in bottles. These are controlled by an operations hub at the core. The wings containing the barrels and bottle cellar are partly embedded into the ground to produce the most favourable environmental conditions for ageing the wine, while the fermentation wing is exposed, allowing carbon dioxide to be released. A road rises to the roof of the building, where the harvested grapes are delivered straight into the hopper: the winery is designed to take advantage of the sloping terrain, using gravity to aid movement of the grapes within the building, maximising efficiency and minimising damage to the grapes. The concrete structure is clad in shingles of Corten steel.

The site in the Ribera del Duero, approximately 150 kilometres north of Madrid, has extremely cold winters, as well as hot summers with limited rainfall. The deep overhang of the roof canopy provides shade and the building is designed to regulate the internal temperatures, at the same time as reducing energy demand. By partly embedding the building within the landscape, its visual impact is minimised and the passive environmental benefits are maximised – the roof incorporates photovoltaic cells and the thermal mass of the concrete structure helps to control interior temperatures.

At the heart of the winery a raised public gallery extends into glazed mezzanine areas, which project deep into each wing, allowing visitors to enjoy elevated views of the different processes. Between the wings is a light-filled public reception and administration area, where extensive terraces and pools of water overlook the vineyards. Lined with deep-stained old wine barrel slats, the public areas are designed to evoke the rich tradition of winemaking in the region.

Lord Foster said:

“Bodegas Portia is our first winery, so we had no preconceptions about how it should work. It was an opportunity to start from first principles – to examine the different stages of wine production and to try to create the ideal conditions for them to unfold. The wine was the starting point, as well as the beautiful setting in Ribera del Duero. Using materials that draw on the region’s winemaking traditions, with public spaces open to the landscape, will enhance the visitor experience.”

Client: Bodegas Faustino SL

Appointment: September 2004

Construction: August 2006 – September 2010

Location: 150km north of Madrid on the main traffic route connecting the major cities in Spain, in the Ribera del Duero region, one of Spain’s foremost wine producing area.

Building Type:Winery – for the production of one million bottles of red wine per year.

Concept: Trefoil plan that reflects the principal process stages: fermentation in steel vats; ageing in oak barrels; and storage and refinement in the bottle.

The two volumes housing the ageing processes are buried into the natural slope of the site, in order to enable gravity-based delivering of the grape harvest. Taking advantage of the thermal cooling benefits of the earth, the building is partly embedded in the landscape.

Operational support and visitors facilities are strategically located in the centre of the building, with the public areas on a mezzanine level. There is also a restaurant with views of the landscape.

Gross Area: 12,500 sqm

Net Area: 11,300 sqm

Site Area: 400 acres

Building Height: 14.5 m (partially embedded into the sloping landscape)

Number of storeys: Two operational levels + grape reception roofdeck (external)

Structure: Concrete structure with pre-cast elements where the structure is exposed and in situ cast concrete where the structure is buried underground, i.e. retaining walls. The boundary link between above and below-grade servicing structures is given visual expression through a continuous linear skylight.

Materials: Materials of building echo the materials used in wine production – steel, oak and glass.

Cladding: Corten Steel shingle cladding to all principal vertical elevations.

Sustainability: The partly buried structure, as well as the concrete framing of the building, maximises its thermal mass to maintain a constant internal environment and the optimal thermal conditions required for the ageing of wine. The wing where the tanks are housed is naturally ventilated to allow CO2 to escape during the fermentation process.

Widescale integration of photovoltaics is anticipated into the design of the roof, spreading over the three wings to maximise the surface for capturing energy.

Production Capacity: One million bottles of red wine per year.

Storage Capacity: 6,000 barrels of 225 litres, and 750,000 bottles.

Client: Faustino SL

Architect: Foster + Partners

Design Team: Norman Foster, David Nelson, Gerard Evenden, Pedro Haberbosch, Nadine Pieper Bosch, Ana Agag Longo, Juan Gabriel La Malfa, Luca Latini, Chris Lepine, Emanuele Mattutini, Josep Mercader, Jaime Valle

Structural Engineer: Arup

Mechanical and Electrical Engineer: Arup

Quantity Surveyor: DLE

Lighting Consultant: Claude Engle

Project Manager: Prointec

Local Architect: Prointec

Main Contractor: FCC

Architects Foster + Partners have designed a winery for Spanish wine producer Faustino Group.

The design, for a trefoil structure in the Ribera del Duero wine region, was launched in Madrid today.

Below is the press release and a project description:

–

Designs for a new winery for the Faustino Group launched

Foster + Partners have unveiled designs for a new winery for the Faustino Group, 150km north of Madrid in the Ribera del Duero, one of Spain’s foremost wine-producing regions. Form follows function to striking effect, with the complex processes rationalised to create the optimum conditions for wine production.

The material palette of oak, steel and glass relates to the production of wine, itself. Visible from one of the main arteries in the country that links Madrid to Bilbao; the winery will be a new symbol for the group, establishing their new brand, Bodegas Portia.

Reminiscent of the naturally undulating topography of the site, a road climbs to the roof of the building, enabling the harvested grapes to be poured straight down into the hopper, where the wine production process begins. The building’s unusual trefoil design is the logical result of a rationalisation of the wine making process into its three core functions. Using gravity to aid movement of the wine within the building, the circulation between the functions is seamless – maximising efficiency and minimising damage to the grapes and wine at their various stages of preparation.

The different needs for each stage – the fermentation in steel vats, ageing in oak barrels and finally, ageing in bottles – dictate the three distinct volumes of the building which are controlled by an operations hub at the core. The wings which house the barrels and bottle cellar are partly sunken below ground, providing the most favourable conditions for ageing the wine, while the fermentation wing is exposed, allowing carbon dioxide to be released.

Partly buried within the landscape, the visible impact of the building is reduced and the passive environmental benefits are maximised, as the concrete structure uses thermal mass to control the internal atmosphere. The building is clad in tiles of earth-toned Corten steel, which further enhances a sense of harmony with the dramatic landscape. The design also incorporates photovoltaic cells on the roof, thus lessening the environmental impact.

A slim line of day-light in the wings of the vast spaces of the winery delineates the ground level, to aid orientation for both visitors and employees. The main visitor facilities are located at the heart of the building, overlooking the operations hub with access to the public areas on glazed mezzanine levels extending to each wing and to the wine tasting in the café and restaurant. Lined with deep-stained old wine barrel slats, they are evocative of the rich tradition of winemaking in the region.

The winery will open in time to process the first harvest of 1.2m kilos of grapes in December 2007.

–

Faustino Winery, Gumiel de Izan, Ribera del Duero, Spain 2004-2007

Client: Faustino SL

Location: 150km north of Madrid on the main traffic route connecting the major cities in Spain, in the Ribera del Duero region, one of Spain’s foremost wine producing areas

Construction: 2006 – December 2007

Net area: 11,300m²

Building type: Winery for the elaboration of one million bottles of red wine per year

Concept: Trefoil plan that reflects the principal process stages. Elaboration, ageing in barrels and ageing in bottles. The two volumes housing the ageing processes are buried in a natural slope in order to be accessible by lorries from above and to make use of the thermal mass. Operational support and visitors facilities are strategically located in the centre of the building with the public areas on a mezzanine level. Restaurant with view of the landscape

Height: 10.5m at the highest point at the centre

Dimensions: Each individual volume is 54 x 37 metres

Structure: Concrete structure with pre-cast elements where the structure is exposed and in situ cast concrete where the structure is buried underground, i.e. retaining walls. The difference between the concrete will be visibly marked by a fine line of light for visitor orientation

Materials: Simple materials used in a winery: steel, glass, wood The public zones will be clad in the burgundy-coloured wooden slats of the barrels.

Energy: The partly buried structure maximises its thermal mass to maintain a constant internal environment and the optimal thermal conditions for the bottles and barrels. The wing where the tanks are housed is naturally ventilated to allow CO2 to escape during the fermentation process.

Photovoltaics have been incorporated into the design on the roof, spreading over the three wings to maximise the surface for capturing energy.